Laser cleaning FAQ

We are frequently asked to provide information on laser cleaning.

This document is a feedback to your most frequently asked questions and a source of information for anyone considering to work with our laser systems. Laser cleaning is a new technology with a huge commercial and industrial application and with many potential customers.

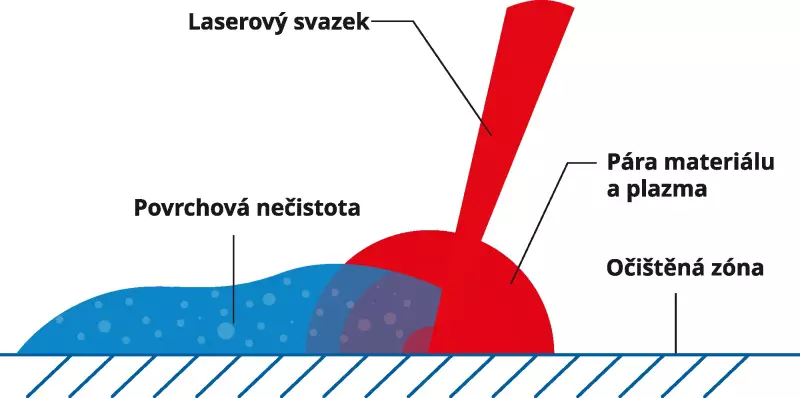

Laser cleaning – how does it work?

Laser cleaning uses focused laser radiation for evaporation of contaminants. The impurities are affected by ultra-short laser pulses (μs-ms), which generate the heat and pressure induced by the heat – high temperature inside the material produces high pressure which induces its evaporation. Laser cleaning is therefore very gentle to the base material. Laser cleaning produces almost no waste because most of the contaminants will evaporate, due to high efficiency of the used laser resonators the operating costs for the cleaning processare very low. Laser cleaning is a non-contact, non-abrasive method which is very gentle to material surface. Considering that the interaction of laser radiation and material depends on the material, it is possible to set the parameters so that the base remains undamaged after cleaning.

Benefits of laser cleaning

- cleaning without damage of the material structure

- fast recovery of your investment

- the lowest operating costs compared to any other industrial cleaning methods (less than 1 EUR/hour)

- speed and efficiency

- easy operation due to user environment

- quick implementation

- sustainability – no addtitional material or chemicals

- zero waste - only minimal or no waste after cleaning

Fields of application

Our lasers have a very large range of applications:

- Corrosion / oxidation removal – the most familiar advantage of laser cleaning. Corrosion can be removed from anywhere, from a small metal nut to big industrial machines.

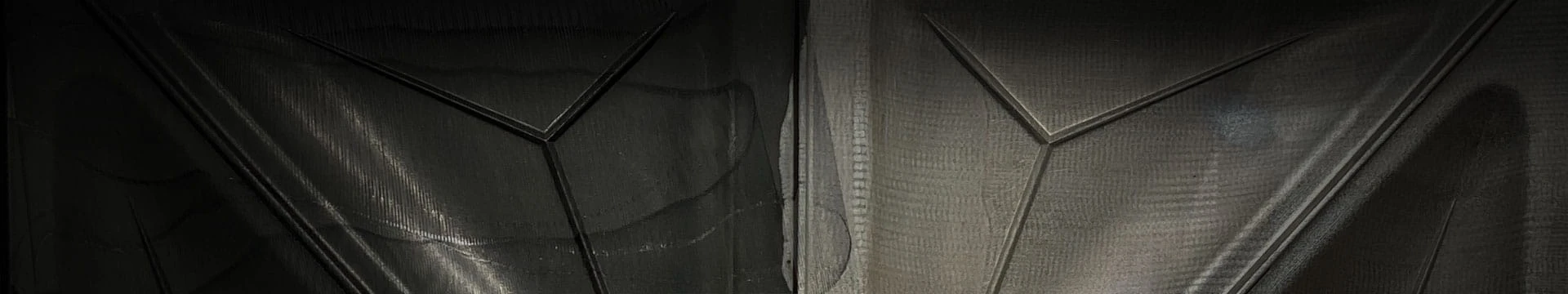

- Removing coatings, surface preparation – laser cleaning is one of the best preparatory processes prior to any type of welding, soldering, gluing or new coating.

- Degreasing – the most frequently used method in processing and manufactoring industry for removing dirt, moisture and other contaminants

- Restoration – laser cleaning is in particular effective for renovation of faded stone and wooden objects, however it is advised to make sure first that the cleaning cannot cause any adverse effects.

- Single parts cleaning – It is not always necessary to clean the entire surface, laser is a perfect choice also for cleaning individual faded parts.

FAQ

What kind of laser do I need for cleaning?

Cleaning lasers from 50 to 1000 W can have very similar results, however they fundamentally distinct in the time they need for the job performance. It is therefore suitable to choose the laser based on the size of the cleaning area, you can find our cost estimates in the chart below.

Lasers can be classified based on their output :

- Low power lasers (50 W – 100 W)

- Medium power lasers (200 W-500 W)

- High power lasers (1000 W – 2000 W)

What are the laser operating costs, how much is one hour of cleaning etc ?

Our lasers are very effective and thus also eco-friendly machines (ISO 14020 and ISO 14024 can be received). For cleaning you don´t need any additional materials (abrasives for blasting, fumes, pdry ice pellets…), the efficiency of laser resonators is up to 50% and so the power consumption is up to 3000W/hour.

Therefore we basically declare, that the hour expenses will not exceed 1 EUR/hour (optics wear, electric power, preventive service).

How is it possible that the laser removes contamination but will not damage the material cleaned?

Properly set and selected laser - with properly set and selected hardware and software - is absorbed in contamination (corrosion, oil, paints, grease, glues, separators…) where it comes to laser ablation, i.e. removal of contamination, however it does not have enough energy to damage material cleaned (steel, aluminium, copper, bronze, brass, stone, sandstone, granite, marble..) therefore it is suitable for cleaning moulds, tools, car components but also for renovation.

How is the laser controlled?

Laser is controlled using a big, well-arranged touch screen. The user can easily select, save and name the individual tasks and parameters for the simple repetition of cleaning. Recently, it is possible to modify the main functions via the ergonomic processing head also during the cleaning process. The system also enables various ways of log-in and to set permissions for the increased safety and process repeatability.

What about the safety?

Mobille cleaning TRON lasers belong to IV class, so it is crucial to keep certain rules of the safe handling. Our lasers usually have a wavelength @1064-1070 nm, it is the area of infrared rediation, to the human eye invisible. Above all, it is necessary to wear the special protective glasses. More rules are specified in a standard EN 60825-1 (will be explained to you during our training).

Protective glasses

We deliver the best quality protective laser glasses with CE certification.

Mobile safety barriers

These barriers are determined for the safety increase or for laser system maintenance.

Will the price of laser drop in the future?

We do not expect that the price of laser systems will drop. The know-how necessary for the production of components and systems is highly specialized and there is no space for distinctive price decrease.

What is the lifetime of a laser?

Lifetime of a resonator, laser source, is around 200 000 operating hours and more.

What are the maintenance costs?

TRON laser machines are conceived as virtually service-free, a common user only takes care of the optical parts to be clean. Preventive service of these machines is not required by Madetron.cz s.r.o. and laser can be used also for non-stop operating.

How long is the hose, cabel, fiber or what do you call it?

The systems are not the same, lower outputs 50, 100, 200 a 300 W have a current limit 10 m, laser with output 500 W can be equipped with a 100 m fiber.

How wide is the laser beam?

The beam itself is a small point, then you have mirrors you need to work with the beam, and so it is possible to scatter it into random shape (lines, circles, rectangles, ellipses etc). The operating width therefore depends on the size you set, on the optics you use, in order to keep the manual feed fluent during cleaning we usually select the width 8 cm. Normally it is possible to choose the distance between 1–10 cm, for special applications up to ca. 30 cm.

What happens if I drive laser over my hand?

If you hit the focusing distance you will burn your hand, if you are out of focus, you will only feel the heat. Laser partly reflects, it is partly absorbed in material, or it can also pass through it.

Can laser remove corrosion?

Removing corrosion with a laser is one of the most effective methods.

Corrosion, paint, oil and other contaminations will not resist laser cleaning.

What is HS code for ordering laser?

HS code for lasers is 90132000 – Lasers, laser, diodes. Lasers (excl. laser diodes)

I found a much cheaper machine from your (mostly) Chinese competitor … Can you explain that?

We present a detailed match of our TRON system and a Chinese product in a case study - see a video below. If two people do the same thing, it is far from the same. Laser device is not a cheap toy, therefore please make sure before you buy a new machine that you are comparing the same machines, the same or similar components and clearly the same services (warranty, service, lifetime of the resonators - their producer, experience with the technology and ergonomic features). We absolutely recommend you to visit the supplier, check the machine carefully and perform the tests. If you are starting with lasers we will be pleased to match the individual machines independantly for you.